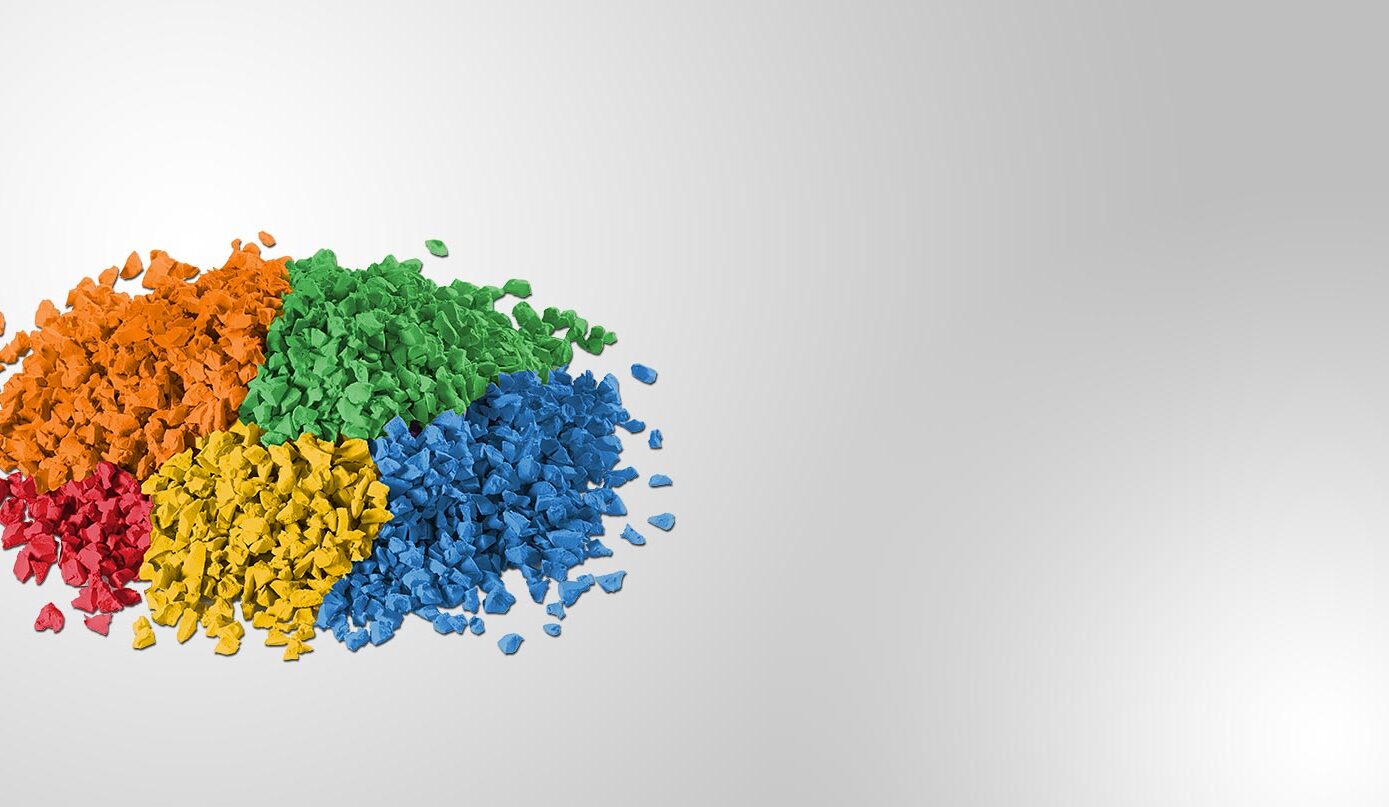

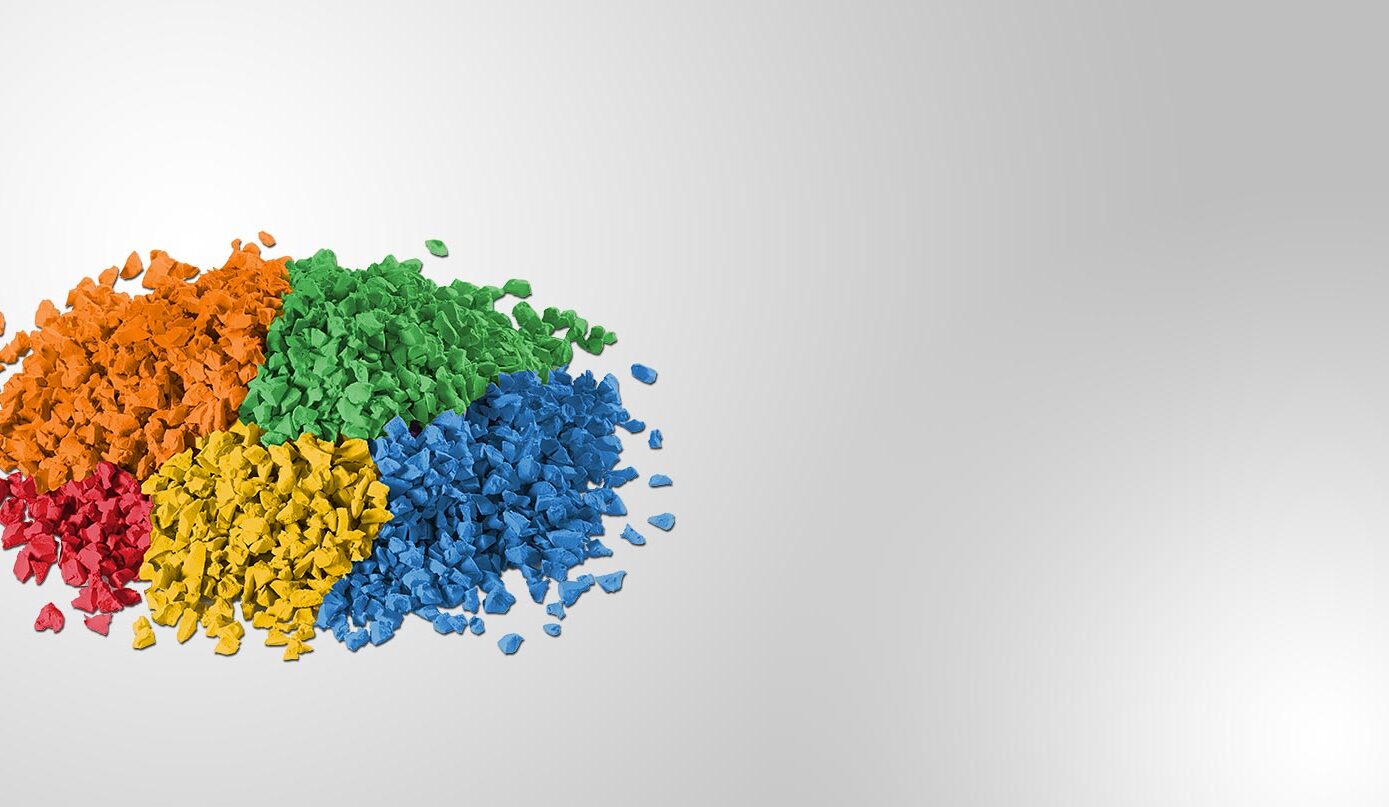

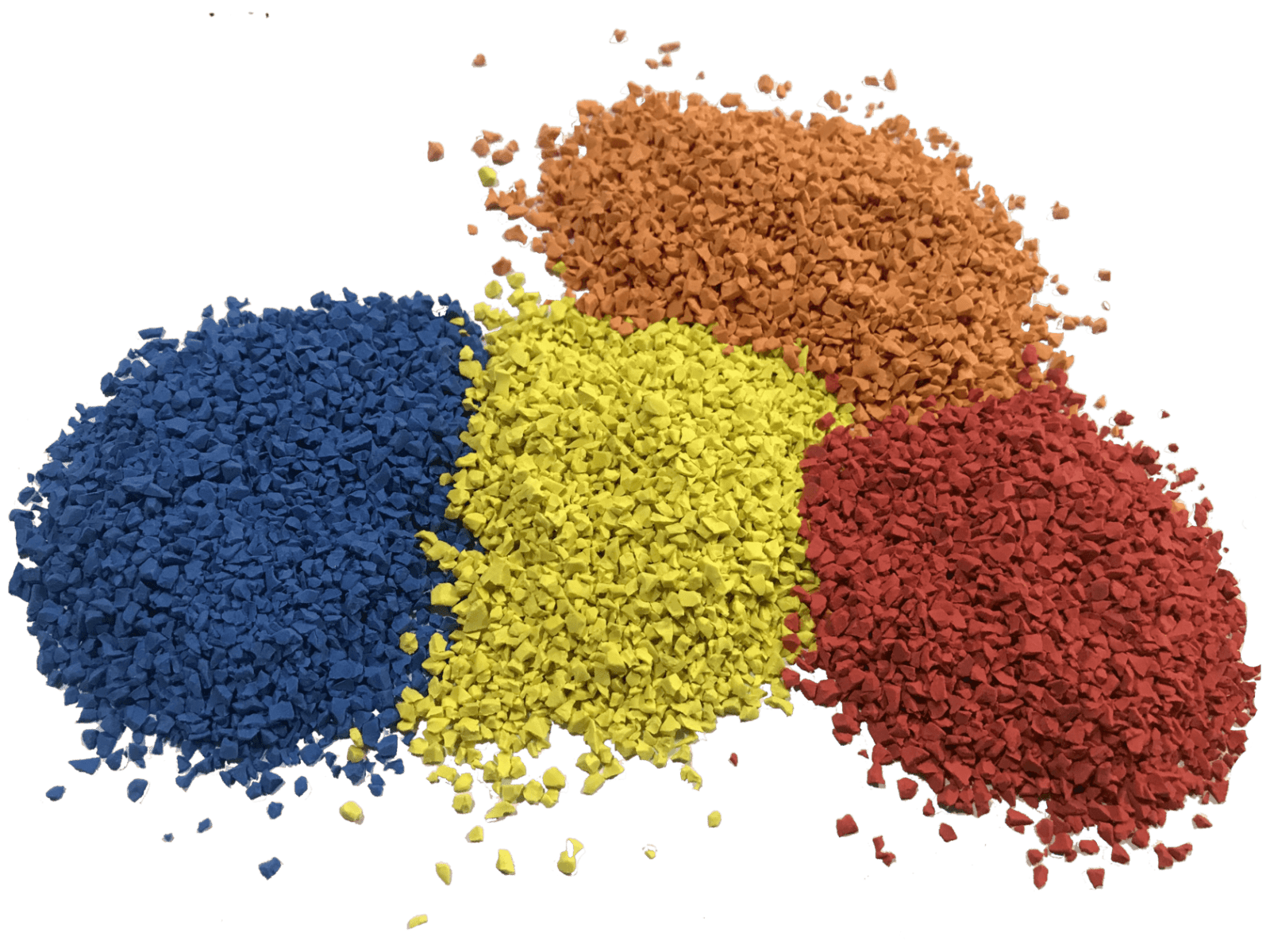

EPDM Granules

What is EPDM Material?

Rubber is a natural product produced by plants and is found in many products used in our daily lives. Rubber has played an important role in human history throughout the development stages of human civilizations.

EPDM is crystallized from ethylene, propylene, and a diene compound. It is widely accepted in industries such as rubber flooring industries. It has high resistance to weather, ozone, and sunlight.

EPDM rubber is an extremely versatile material that can be used in a variety of applications. It also serves as a more affordable alternative to silicone and can last for long periods with proper use, saving both time and money.

Properties

The EPDM (Ethylene Propylene Diene Monomer) sheet provides excellent resistance to weathering, ozone, and UV exposure. It is highly recommended for applications where synthetic rubber is highly exposed to the environment. It provides excellent chemical resistance and dynamic properties.

- Common Name: EPDM

- ASTM D-2000 Classification: CA

- Chemical Definition: Ethylene Propylene Diene Monomer

- Temperature Range:

- Low-Temperature Use: -20°F to -60°F | -29°C to -51°C

- High-Temperature Use: Up to 350°F | Up to 177°C

- Tensile Strength:

- Range: 500-2500 PSI

- Elongation: 600% maximum

- Hardness (Shore A): 30-90

- Flexibility/Resilience: Good

- Wear Resistance: Good

- Tear Resistance: Fair

- Compression Set: Good

Additional Properties:

- Weather Resistance - Sunlight: Excellent

EPDM Granule Properties for Playground Flooring:

- Good color stability

- High flexibility and wear resistance

- Resistance to acids and alkalis

- UV resistance properties

- Low density for excellent coverage

- Excellent features for wet safety playgrounds

Usages

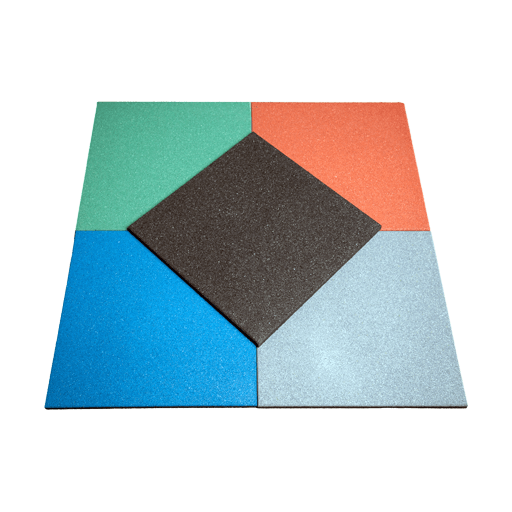

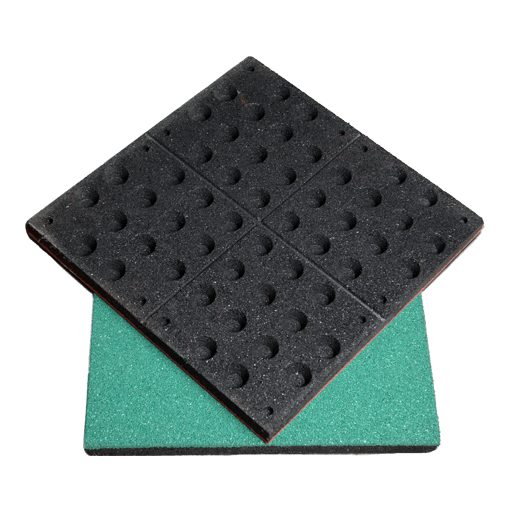

Square Tile Design

Square Tile Design Hollow Design Square Tiles

Hollow Design Square Tiles Square Tile Design Deflated

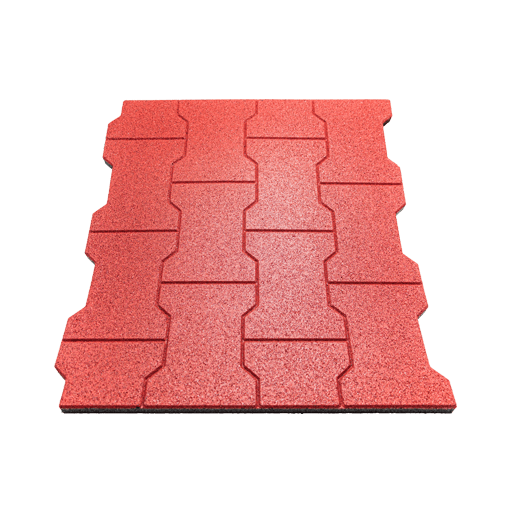

Square Tile Design Deflated Buzzle Basic

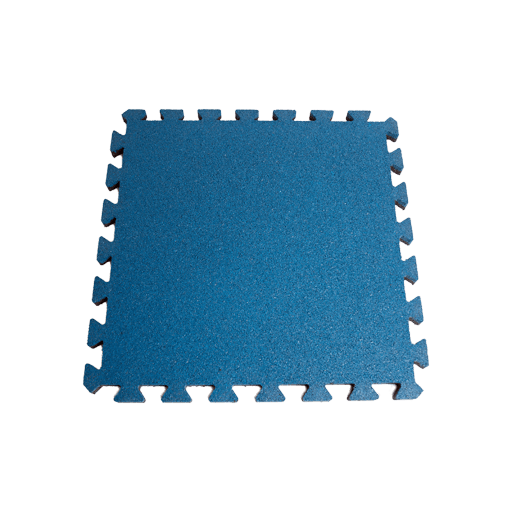

Buzzle Basic Interlock Tiles

Interlock Tiles 60 cm Interlock Tiles

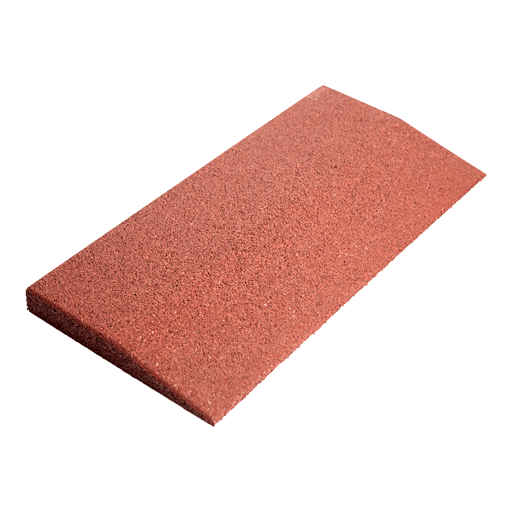

60 cm Interlock Tiles Ramp Tiles

Ramp Tiles Plain Black Rubber Roll (SPR)

Plain Black Rubber Roll (SPR) Black Rubber Roll with EPDM Granules

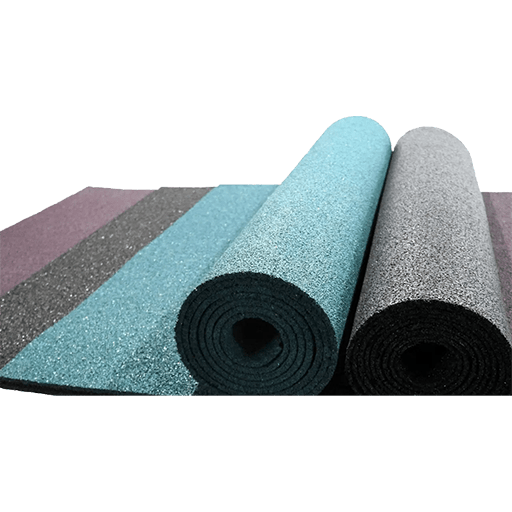

Black Rubber Roll with EPDM Granules Pure EPDM Rubber Roll

Pure EPDM Rubber Roll Colored Rubber Roll with Black EPDM Granules

Colored Rubber Roll with Black EPDM Granules SBR Granules and Rubber Powder

SBR Granules and Rubber Powder EPDM Granules

EPDM Granules On-Site Installation System

On-Site Installation System